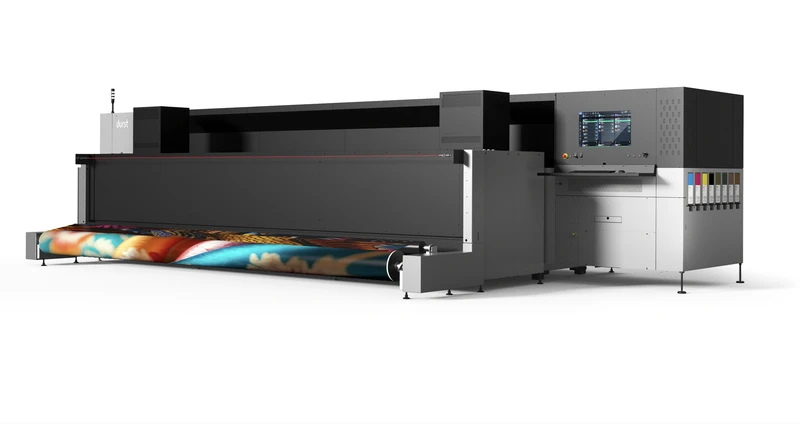

Virtual showroom

In the Virtual Showroom you will find detailed information and specifications on Durst printing systems. The respective content is updated regularly and you will also find the latest updates here.

Multipurpose ink with balanced stackability and flexibility, a wide adhesion range combined with larger color gamut make this ink suitable for many applications.

This versatile ink is particularly suitable for flexible media applications requiring a wide adhesion range and very good flexibility.

High volume production ink, ideally suited for paper surfaces and tack sensitive applications even at highest print speed conditions.

This highly flexible ink is particularly suitable for materials that demand highest flexibility, such as lightbox textiles, transparent films, banner and day & night applications.

Groundbreaking sublimation ink for direct inline fixation and transfer printing of polyester substrates.

Unique primary food packaging compliant water-based ink for corrugated and cardboard applications.

The GOTS-certified Durst reactive inks were developed for classic applications such as home textiles, curtains, bed and sofa covers, clothing and fashion. They are suitable for printing cotton and cotton blends with a cotton content greater than 60% as well as polyamide and silk.

The pigment ink system specially developed by Durst can be used universally in the textile sector. It is characterized by excellent color rendering and a soft feel at the same time. Pre- and post-treatment steps are omitted in most standard applications, so that the highest level of economic efficiency is guaranteed in production.

Our new generation of dye-sub ink, SUBLIFIX, provides optimum performance for a wide range of Soft Signage & Fabrics applications:

The water-based Durst WT Food MP ink is used in Delta Multi-Pass printing systems to produce high-quality printed products in multi-pass printing. For example, skin tones can be reproduced more naturally through the targeted use of light colors. The ink can be used for primary food packaging as well.

This water-based ink, designed for extremely fast printing processes on corrugated cardboard, is used in the Delta single-pass printing line. It can be used to produce high-quality, odor-free, abrasion-resistant, glossy and lightfast corrugated cardboard products - in line with the requirements of the packaging industry. The ink can be used for primary food packaging as well.

Rho POP HS was specially developed to produce high print volume cost-efficiently. This high-gloss ink makes it possible to eliminate additional finishing processes such as high-gloss lamination, making the overall production process more efficient. POP HS ink is a very versatile ink that is suitable for printing on paper surfaces as well as on Forex, dibond, and styrene. The particularly large color space and the gloss finish make this ink suitable for a broad range of applications.

This ink was developed for inexpensive and odor-reduced printing on paper surfaces, corrugated displays, posters, and packaging. It has been optimized with regard to application specific criteria to allow, for example, 360-degree bending when post-processing paper surfaces. The ink is suitable for printing on coated and semi-coated paper as well as uncoated, absorbent paper surfaces. Its hard surface allows it to be stacked easily and further processed without abrasion.

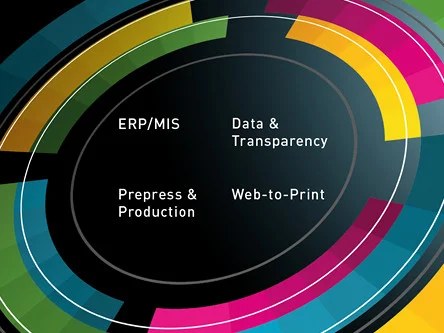

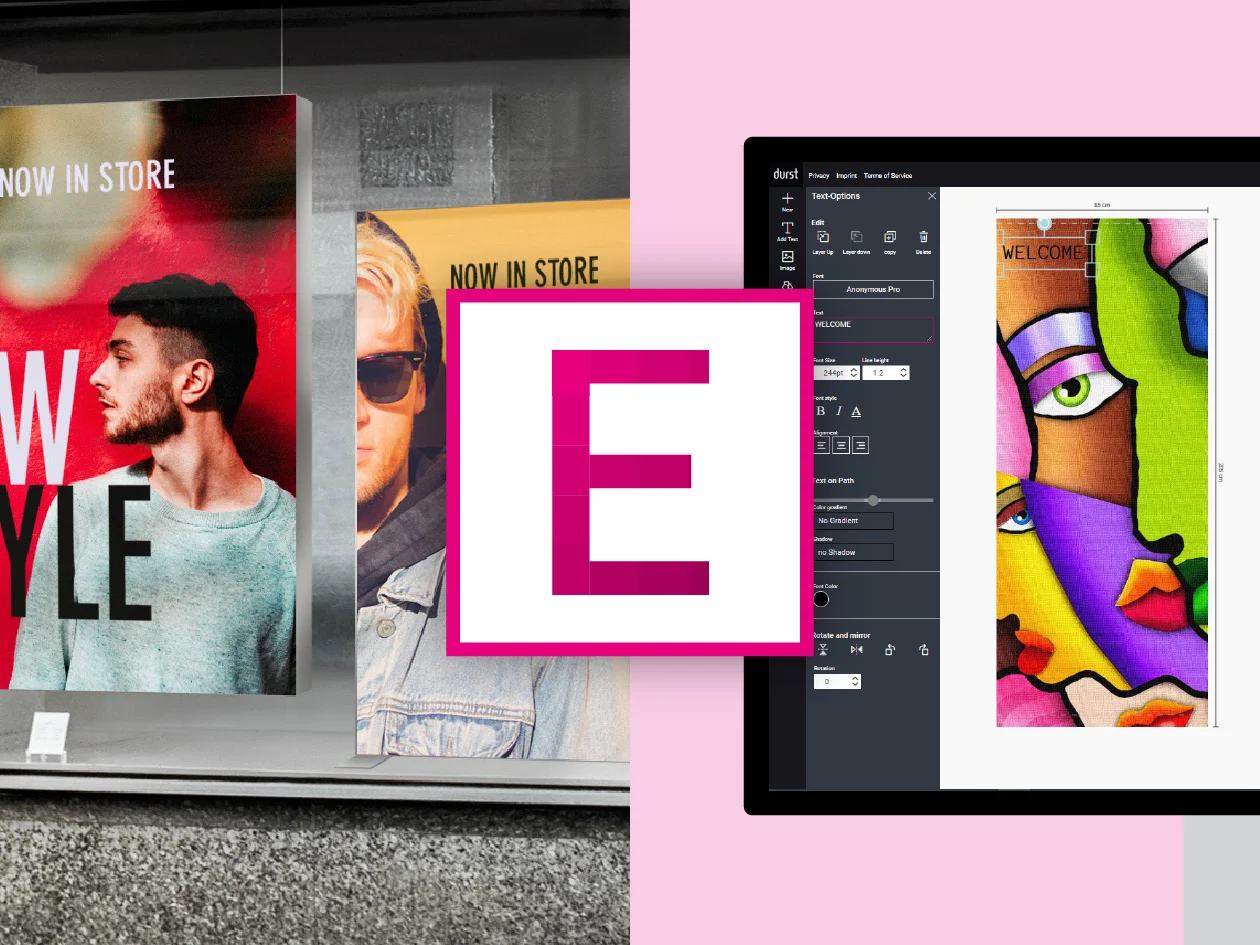

Take your e-commerce to the next level with our fully customizable online editor designed specifically for the print industry. Smart Editor is a graphical online editor that allows you to design personalized print products directly in your web browser. Compatible with most e-commerce solutions on the market, it is designed to provide a superior print shopping experience for your customers, while generating printable PDF files and automating your web-to-print processes. Whether your focus is on large format, corrugated or label business, our solution empowers you to deliver a personalized and impactful experience to your customers, boosting your online presence, increasing your print shop's conversion rate and setting you apart in the competitive marketplace.

Catering to wide range of large format printing applications, our editor is the gateway to creating posters, canvas art, beach flags, banners, wallpapers, cards and much more.

Food, beverage, cosmetic labels and more: our versatile label editor is the perfect choice to step up your online label printing business.

Discover boundless creativity through our editor: allow your customer to personalize packaging boxes, gift boxes, point of sales (POS), shelfs, temporary furniture and structures, promotional cutouts for marketing campaigns and much more.

In the Virtual Showroom you will find detailed information and specifications on Durst printing systems. The respective content is updated regularly and you will also find the latest updates here.

Convert your customers’ artwork in no time into printed product. The generated orders from the editor are received as print predictable PDF files, including all technical details and cutting paths, ready to be transferred to production.

Durst Smart Editor is easily integrated into your existing web shop via plug-in or API. Compatible with most of the e-commerce solutions on the market, our graphic online editor doesn’t require additional software to work.

Thanks to 3D previews and mockups preview it is easy to enhance the perceived value of the product, contributing in increasing the trust toward the product and your e-commerce conversion rate.

Allow your customers to turn their vision into reality thanks to Durst Smart Editor's user-friendly editing tools. Give them access to a range of features such as text tools, smart guidelines, intelligent image background removal, and pre-defined templates. These tools make the order placement process seamless, intuitive, and efficient, ensuring that your customers can easily create their desired designs with confidence.

In our corrugated editor, customers can also easily define custom cutouts and punches within their packaging designs, allowing them to create the perfect package. Additionally, customers have the option to download a 2D cutout diagram, which can be used to design packaging in an external program. The designed packaging can then be loaded into our editor for a streamlined order process. Furthermore, our editor supports FEFCO and ECMA standards, ensuring compliance and design accuracy.

Ensure flawless print quality every time. Our editor is seamlessly connected to Durst image databases, offering access to millions of high-resolution images, and Pattern design, providing a wealth of seamless vector patterns. If you prefer, you can also link the editor to your own image database. Customers can upload their files and independently verify image resolution with our integrated 'image quality check' feature, assuring outstanding printing results.

Multipurpose ink with balanced stackability and flexibility, a wide adhesion range combined with larger color gamut make this ink suitable for many applications.

This versatile ink is particularly suitable for flexible media applications requiring a wide adhesion range and very good flexibility.

High volume production ink, ideally suited for paper surfaces and tack sensitive applications even at highest print speed conditions.

This highly flexible ink is particularly suitable for materials that demand highest flexibility, such as lightbox textiles, transparent films, banner and day & night applications.

Groundbreaking sublimation ink for direct inline fixation and transfer printing of polyester substrates.

Unique primary food packaging compliant water-based ink for corrugated and cardboard applications.

The GOTS-certified Durst reactive inks were developed for classic applications such as home textiles, curtains, bed and sofa covers, clothing and fashion. They are suitable for printing cotton and cotton blends with a cotton content greater than 60% as well as polyamide and silk.

The pigment ink system specially developed by Durst can be used universally in the textile sector. It is characterized by excellent color rendering and a soft feel at the same time. Pre- and post-treatment steps are omitted in most standard applications, so that the highest level of economic efficiency is guaranteed in production.

Our new generation of dye-sub ink, SUBLIFIX, provides optimum performance for a wide range of Soft Signage & Fabrics applications:

The Tau RSC UV ink set is used in the Tau 340 RSC E, Tau 340 RSC and the Tau RSCi press. During development the focus was on excellent flow characteristics and high edge sharpness.

The Tau RSC Low Migration inks have been developed specially for applications in the food, beverage, cosmetics and pharmaceutical markets.

The inks have been formulated based on the common regulation and tested and declared as compliant by independent test institutes.

The water-based Durst WT Food MP ink is used in Delta Multi-Pass printing systems to produce high-quality printed products in multi-pass printing. For example, skin tones can be reproduced more naturally through the targeted use of light colors. The ink can be used for primary food packaging as well.

This water-based ink, designed for extremely fast printing processes on corrugated cardboard, is used in the Delta single-pass printing line. It can be used to produce high-quality, odor-free, abrasion-resistant, glossy and lightfast corrugated cardboard products - in line with the requirements of the packaging industry. The ink can be used for primary food packaging as well.

Rho POP HS was specially developed to produce high print volume cost-efficiently. This high-gloss ink makes it possible to eliminate additional finishing processes such as high-gloss lamination, making the overall production process more efficient. POP HS ink is a very versatile ink that is suitable for printing on paper surfaces as well as on Forex, dibond, and styrene. The particularly large color space and the gloss finish make this ink suitable for a broad range of applications.

This ink was developed for inexpensive and odor-reduced printing on paper surfaces, corrugated displays, posters, and packaging. It has been optimized with regard to application specific criteria to allow, for example, 360-degree bending when post-processing paper surfaces. The ink is suitable for printing on coated and semi-coated paper as well as uncoated, absorbent paper surfaces. Its hard surface allows it to be stacked easily and further processed without abrasion.