Durst Workflow Label: the prepress and production software for your business growth

In the fast-paced world of label production, staying competitive and meeting customer demands can present various challenges that need to be addressed. These challenges include implementation hurdles, time-sensitive projects, quality control requirements, and customization requests. By effectively tackling these obstacles, label printing businesses can enhance their efficiency and profitability, ensuring smooth operations and delivering high-quality products that meet customer expectations.

Durst Workflow Label is the all-in-one solution to manage your prepress and print production tasks in the most efficient way, effectively overcoming these challenges.

Implementation of the software into your existing IT

Implementing new software can be daunting, but we've simplified the process. We understand the criticality of your existing IT environment to your operations. That's why our solution is designed to integrate effortlessly with your current setup, eliminating any compatibility concerns and allowing you to fully leverage your existing technology investments. Our solution requires minimal effort to set up, ensuring a smooth transition for your team.

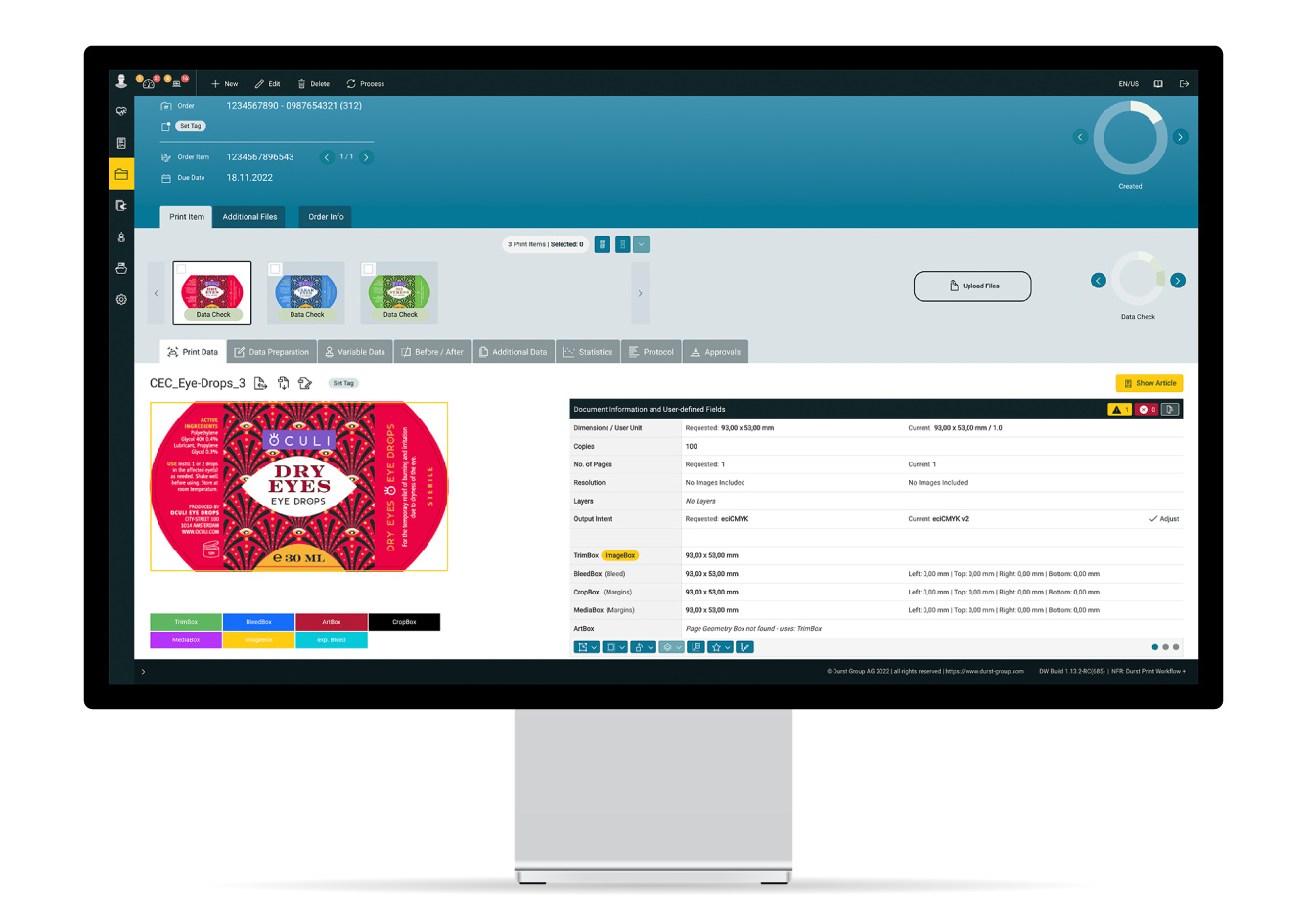

Multiple systems complexities

From the initial prepress to the final production, our comprehensive platform offers a seamless and complete solution, ensuring a smooth workflow and eliminating the need for multiple disjointed systems. With a focus on simplicity and functionality, our user-friendly interface ensures that even newcomers can quickly adapt to the system without significant implementation effort, enabling an efficient production experience.

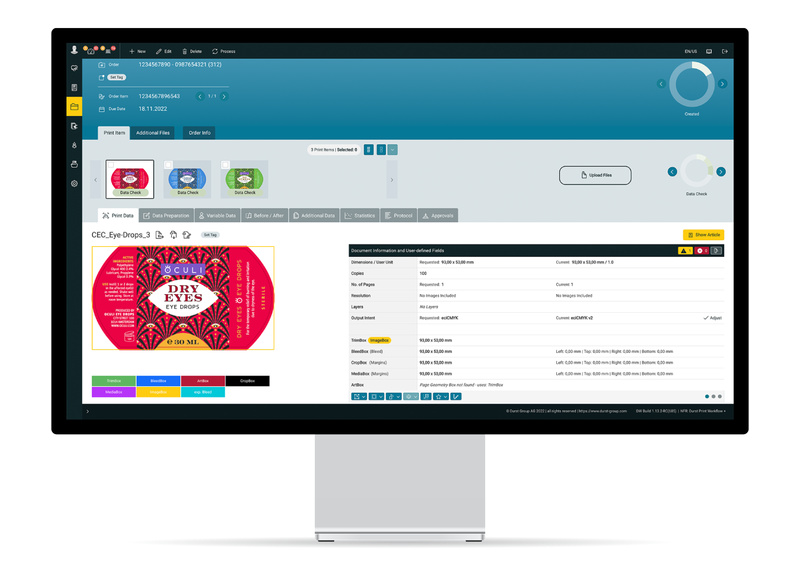

Optimizing Resource Allocation

Data preparation is a time-consuming aspect of label production. However, Durst Workflow Label's automation capabilities simplify the process. Intelligently automating data preparation per product reduces human intervention, expediting the production timeline. With streamlined resource allocation, your team experiences increased productivity and quicker turnaround times.

Handling time-sensitive projects

Time-sensitive projects demand precision and efficiency. Durst Workflow Label empowers your business with easy management of short runs and just-in-time production, optimizing your workflow for better results. With quick turnaround times, you can meet tight deadlines without compromising quality, gaining a competitive edge in the market.

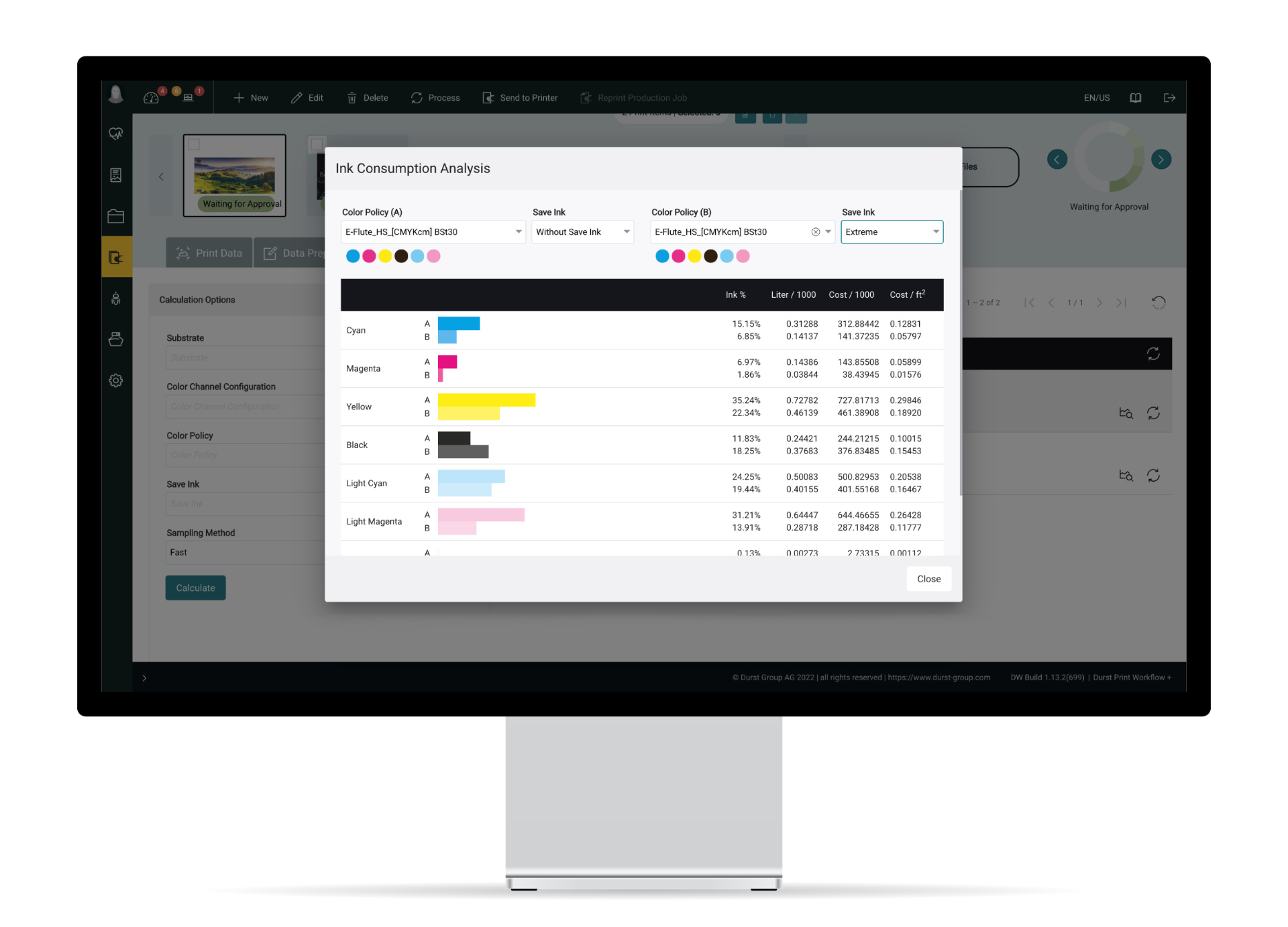

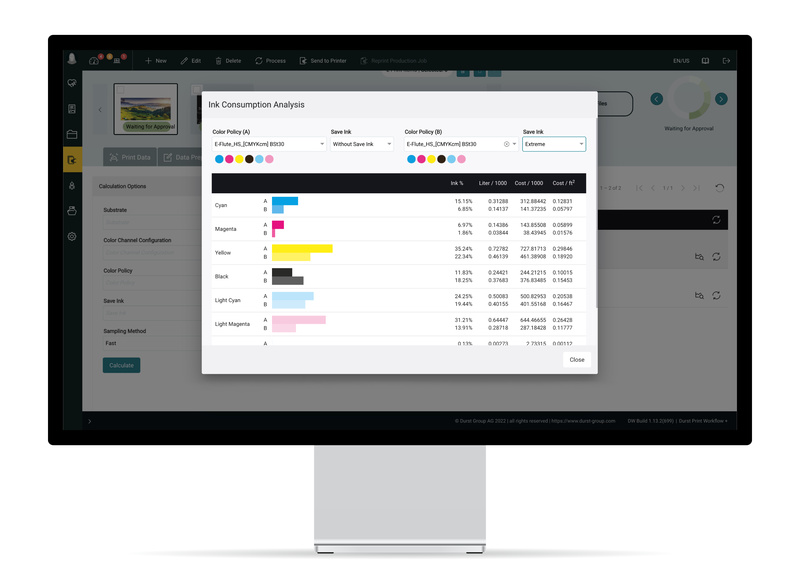

Reducing Waste and Ink Consumption

Durst Workflow Label's Ink Save feature automatically calculates the best color combination to minimize ink usage on the substrate. By optimizing ink consumption for all colors in your printer and compensating with black ink, the software ensures efficient reduction of total ink usage, reducing your TCO and environmental impact.

Embracing Customization Requests

In the era of personalization, customization requests are on the rise. Durst Workflow Label's Variable Data Printing (VDP) capabilities enable you to produce customized print jobs faster than ever, eliminating manual file handling. Embrace customer demands for personalized labels and boost customer engagement with ease.

Ensuring Color Consistency

Brand consistency is paramount in the label printing industry. With advanced brand and spot color management, Durst Workflow Label helps you maintain consistency and make a lasting impression. Achieve accurate color reproduction across different printing runs and materials, reinforcing your brand identity.

Embrace the future of label production and unlock your full potential with our easy-to-use and highly efficient platform, while maintaining the high-quality standards your business demands with Durst Workflow Label.