Topics:

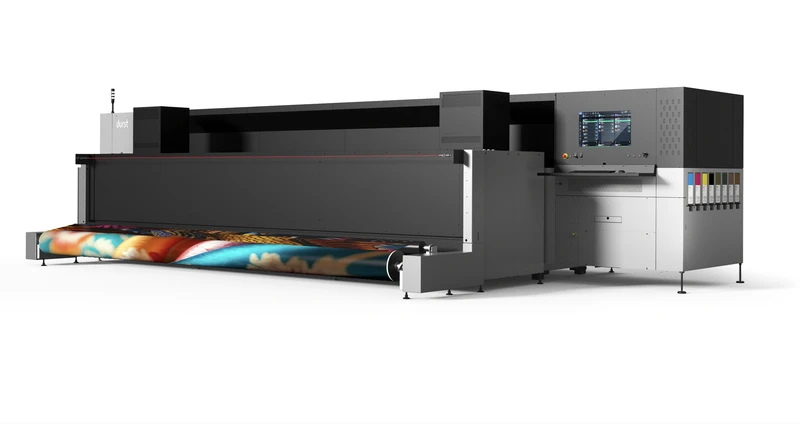

- description of the device

- general operation

- basic functionality

- preparation of materials

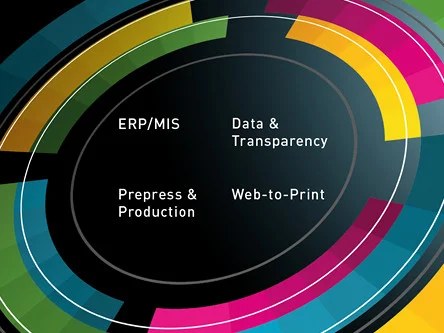

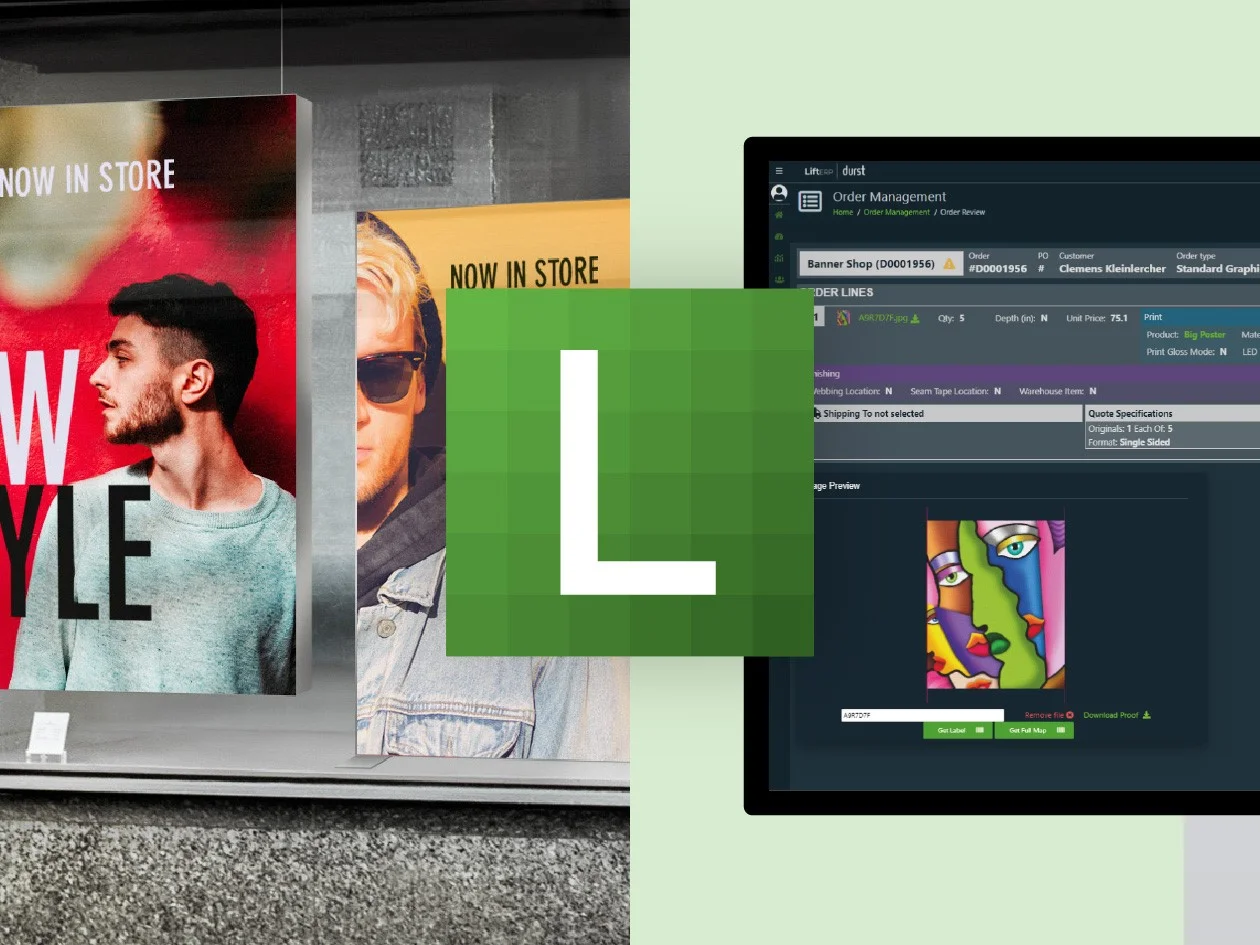

- introduction to the operating software

- device settings

- evaluating the print quality

- general maintenance tasks

Goals:

After successfully completing this program, participants can operate and maintain the printing system to guarantee a smooth and flawless printing process.