Ceramics

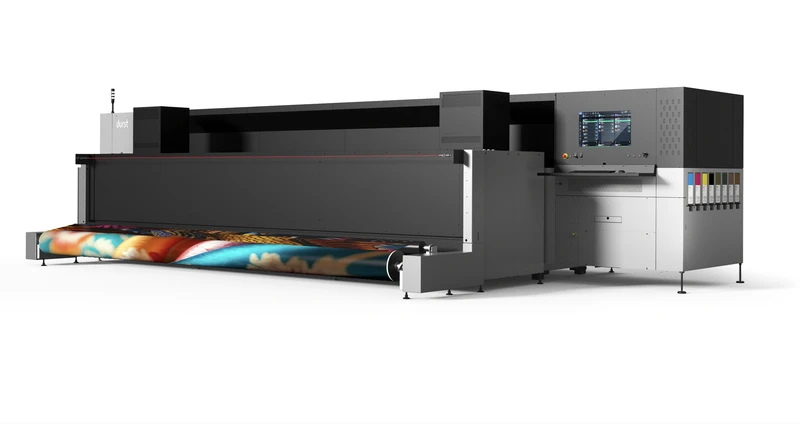

Durst is a technological leader in the ceramic tile production and has been the first manufacturer to develop and sell a digital single pass ceramic printer for pigmented inks back in 2004 which has revolutionized the tile decoration and significantly increased print quality, product design and production efficiency.

Thanks to the very close cooperation with customers and the continuous further development the latest Gamma XD Series are widely recognized by customers as the best performing digital ceramic décor printers thanks to its unmatched print quality with no banding or lines, very high uptime (97-100%) with no print head replacements and very low maintenance and service costs.

In the past years Durst has developed a completey new print head technology , Durst RockJET™, for digitally printing structures on flat tiles using almost standard ceramic glazes with large particle sizes (>45µm), which has now initiated the next revolution in ceramics through a real technological innovation.