SAVE UP TO 35% INK WITH DURST WORKFLOW INK SAVE TOOL

Discover Durst Workflow Ink Save tool

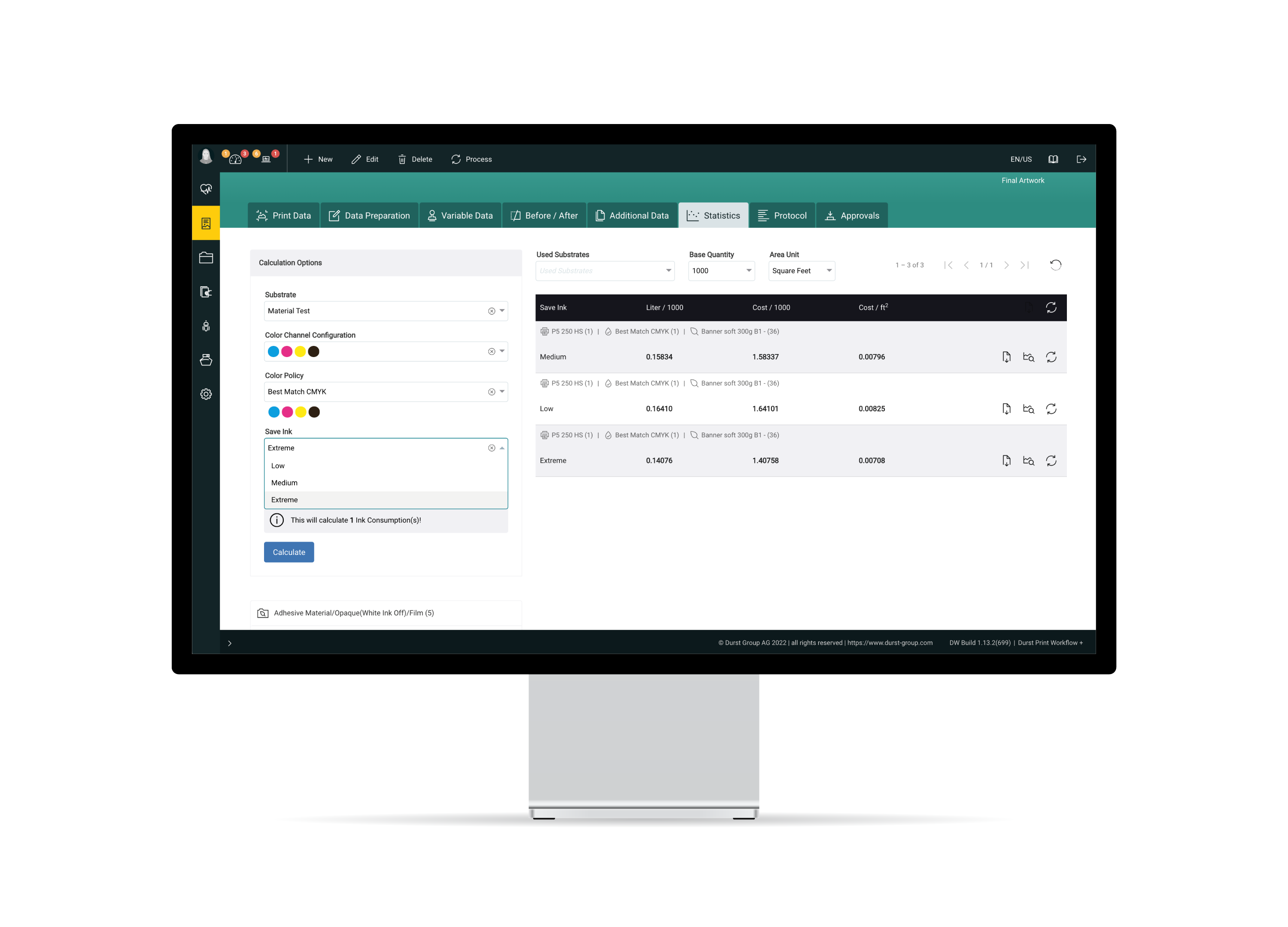

Ink Save is a module of Durst Workflow software developed to help inkjet printers reduce ink consumption while maintaining excellent color accuracy. Easy to use, Ink Save adjusts the ink consumption of all colors in your printer and compensates with black to achieve optimal reduction of your total ink consumption.

Designed for Durst printers, Ink Save has optimized presets to ensure the optimal ink saving configuration. Durst Workflow Ink Save is now also available for third party printers to maximize savings and ensure color accuracy across your entire printing devices.

How does the Ink Save tool work?

You don’t need to be a color expert to save on ink with Durst Workflow: its integrated powerful engine automatically calculates the color combination that reduces the amount of ink printed on the substrate. The Ink Save tool adjusts the ink consumption of all colors in your printer and compensates with black to achieve optimal reduction of your total ink consumption. Check ink consumption before printing: calculate and compare the ink consumption of your job in advance and compare the amount of ink usage with/without the feature or with different ink save modes to find the solution that best suits your needs. No re-profiling is needed.

In addition, Grey Component Replacement (GCR), being one part of the used algorithms, enables the right balance between ink savings and smoothness. In Durst Workflow the CMY values that add up to gray in the tone scale are replaced with black ink. The use of light black ink further supports this GCR approach, as the reduced contrast of light black allows for the best possible uniformity by replacing CMY. It results in less ink consumption, consequently thinner ink layers and optimized drying, which is especially valuable for high-speed printing and is also reflected in simplified post-printing processes. This function is as well applied automatically, so you don´t have to change it manually.

Why should you use this feature?

In this day and age, attention to issues around environmental sustainability and resource saving is imperative, as economic development and sustainability increasingly emerge as strongly related issues. Through the Ink Save tools, we help our customers reduce ink consumption and production costs by offering a choice of 3 different ink saving levels: low, medium and extreme. By using the extreme level, it is possible to save up to 35% on ink consumption.

Besides the significant environmental advantage of this, it is also a considerable figure for our customers' return on investment (ROI), which also helps reduce the total cost of ownership (TCO).

Durst Workflow Ink Save tool enables our customers to save up hundreds of liters of ink yearly while maintaining excellent color accuracy.

The higher your ink consumption, the faster you will get a return on investment.

For example, if you use 2 Durst large-format printers you may print between 300.000 m2 and 400.000 m2 per year you could achieve ink savings between 50 and 100 liters per month.

Ink Save can be activated or deactivated in Durst Workflow user interface. Just select the ink saving level you want to apply, and the engine will do it for you. No re-profiling is needed.

Reducing ink consumption has significant benefits in terms of sustainability and allows cost-effective production.

The Ink Save tool allows you to apply less ink on the media, allowing faster drying and therefore a faster process of post-printing operations.

What our customers say

"By integrating Durst Workflow with the ERP system, we were able to make the manufacturing process much more transparent. Every department in the company now has insight into where the job is located. As a result, lead time has been optimized by 18%."

"We now use ink saving software feature from Durst Workflow for about 80% of our print jobs. Without any loss in quality, we have thus realized a cost saving of 34% per m² in the last fiscal year. This makes digital printing even more attractive in comparison to conventional printing."

Niko von Hanstein

Head of Production and Prepress

Clever Systemtechnik GmbH

"In mid-2022, we installed a P5 HS 350 with Durst workflow software. We mainly print weatherproof posters on polypropylene. Our daily print volume on this machine is normally between 2,000 and 5,000 square meters. With this volume, efficient color management is extremely important."

"For most posters, we opt for a "Medium" color setting, which allows us to save up to 15% ink. For larger print runs, we can even save up to 25% ink with the "Extreme" mode, depending on the motif."

Gerhard Klein

CEO

Braun und Klein