- Large Format

- Soft Signage & Fabrics

- Textile

- Labels

- Ceramics

- Corrugated

- Hybrid

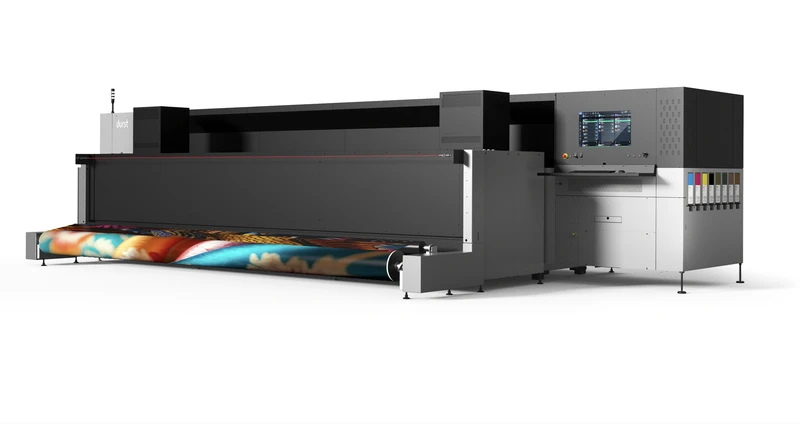

- P5 210/HS

- P5 350/HS

- P5 350 HS Pack

- P5 SMP™

- Roll-to-Roll

- P5 350 HSR

- P5 500

- Flatbed

- P5 X

- Billboards & Posters

- LF BB Series

- Automation

- Automat MT

- P5 Robotics

P5 Series

A matter of efficiency

Soft Signage & Fabrics

Sustainable, High-Impact Visuals

- Alpha 330 Textile Edition

- Alpha Wallpaper Edition

- Alpha 190 Textile Edition

- Alpha DyeSub Edition

- P5 350 TEX iSUB

- P5 500 TEX iSUB

Alpha Series

Tau Series

Gamma Series

Corrugated

- Traffic signs

- Soft signage & fabrics

- Corrugated packaging

- Industrial decoration

- Indoor decoration

- Outdoor application

- Signage and advertising

Large format

Discover more- Soft Signage Printing

- Wallpaper Printing

- Home Textile Printing

- Athleisure & Sportswear Printing

- Digital Fashion Printing

Textile

Discover more- Variable data

- Speciality packaging

- Industrials

- Pharmaceuticals

- Online printing

- Chemicals

- Food & beverages

- Beauty & care

- Wine & spirits

Labels

Discover more

Corrugated

Discover more- Large Format

- Labels

- Corrugated

- P5 350 HSR

- P5 350/HS

- P5 210 HS

- P5 TEX iSUB

- P5 500

- Automat MT

- Tau RSCi

- Tau 340 RSC E

- Tau 340 RSC E LM

- Tau 340 RSC

- Tau G3 Peak

- Tau G3 Core

- P5 350/HS

Aturion LED Ink

Multipurpose ink with balanced stackability and flexibility, a wide adhesion range combined with larger color gamut make this ink suitable for many applications.

Roll LED Ink

This versatile ink is particularly suitable for flexible media applications requiring a wide adhesion range and very good flexibility.

Pop flexible LED Ink

High volume production ink, ideally suited for paper surfaces and tack sensitive applications even at highest print speed conditions.

FLT LED Ink

This highly flexible ink is particularly suitable for materials that demand highest flexibility, such as lightbox textiles, transparent films, banner and day & night applications.

P5 Sublifix Ink

Groundbreaking sublimation ink for direct inline fixation and transfer printing of polyester substrates.

WT Food MP Ink

Unique primary food packaging compliant water-based ink for corrugated and cardboard applications.

Reactive - The Cotton Ink

The GOTS-certified Durst reactive inks were developed for classic applications such as home textiles, curtains, bed and sofa covers, clothing and fashion. They are suitable for printing cotton and cotton blends with a cotton content greater than 60% as well as polyamide and silk.

Pigment - Universal Textile Ink

The pigment ink system specially developed by Durst can be used universally in the textile sector. It is characterized by excellent color rendering and a soft feel at the same time. Pre- and post-treatment steps are omitted in most standard applications, so that the highest level of economic efficiency is guaranteed in production.

Subliflix Dye-Sub Ink

Our new generation of dye-sub ink, SUBLIFIX, provides optimum performance for a wide range of Soft Signage & Fabrics applications:

Tau Inks

Discover more

Tau Inks

Discover moreWT Food MP Ink

The water-based Durst WT Food MP ink is used in Delta Multi-Pass printing systems to produce high-quality printed products in multi-pass printing. For example, skin tones can be reproduced more naturally through the targeted use of light colors. The ink can be used for primary food packaging as well.

WT Food SP Ink

This water-based ink, designed for extremely fast printing processes on corrugated cardboard, is used in the Delta single-pass printing line. It can be used to produce high-quality, odor-free, abrasion-resistant, glossy and lightfast corrugated cardboard products - in line with the requirements of the packaging industry. The ink can be used for primary food packaging as well.

RHO POP HS Ink

Rho POP HS was specially developed to produce high print volume cost-efficiently. This high-gloss ink makes it possible to eliminate additional finishing processes such as high-gloss lamination, making the overall production process more efficient. POP HS ink is a very versatile ink that is suitable for printing on paper surfaces as well as on Forex, dibond, and styrene. The particularly large color space and the gloss finish make this ink suitable for a broad range of applications.

RHO Paper and Board 30 DM Ink

This ink was developed for inexpensive and odor-reduced printing on paper surfaces, corrugated displays, posters, and packaging. It has been optimized with regard to application specific criteria to allow, for example, 360-degree bending when post-processing paper surfaces. The ink is suitable for printing on coated and semi-coated paper as well as uncoated, absorbent paper surfaces. Its hard surface allows it to be stacked easily and further processed without abrasion.

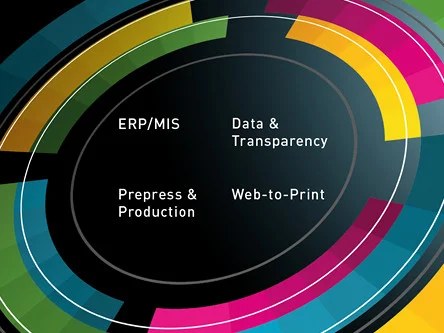

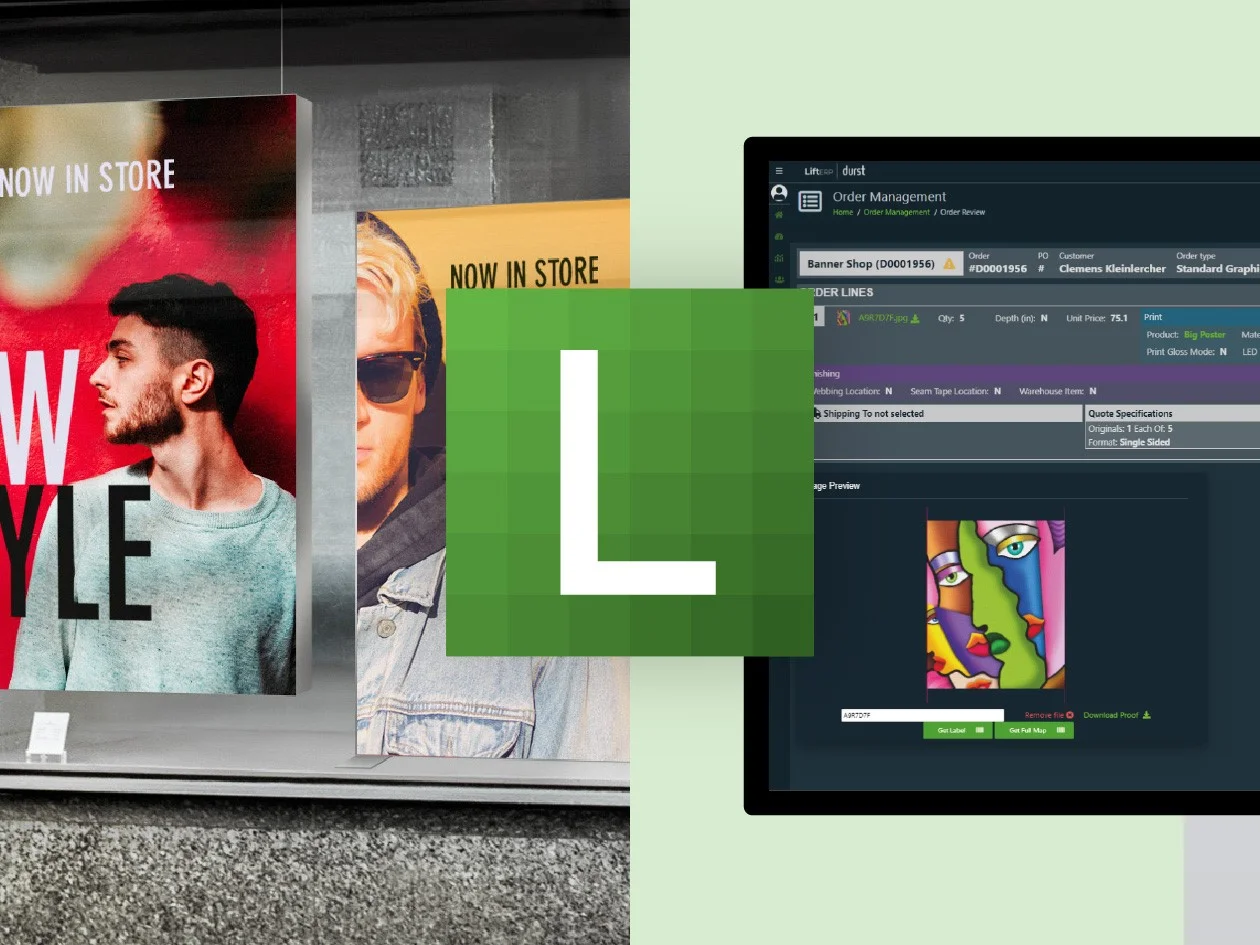

- Software overview

- ERP / MIS

-

Web to Print

Ecommerce -

Web to Print

Editor -

Prepress &

Production -

Data &

Transparency

ERP / MIS

Discover more

Web to Print

Ecommerce

Discover more

Web to Print

Editor

Discover more

Prepress &

Production

Discover more

Data &

Transparency

Discover more

- Large Format

- Soft Signage & Fabrics

- Textile

- Labels

- Ceramics

- Corrugated

- Large Format

- Textile

- Labels

- Ceramics

- Corrugated

- Large Format

- Labels

- Corrugated

- P5 350 HSR

- P5 350/HS

- P5 210 HS

- P5 TEX iSUB

- P5 500

- Automat MT

- Tau RSCi

- Tau 340 RSC E

- Tau 340 RSC E LM

- Tau 340 RSC

- Tau G3 Peak

- Tau G3 Core

- P5 350/HS

- Durst Group

- Durst in the world

- Suppliers

- Sustainability