Durst Smart Factory

EMBRACING PRINT 4.0 WITH DURST SOFTWARE AND SOLUTIONS

Industry 4.0, which is synonymous with smart manufacturing, refers to a new paradigm of industrial production processes that significantly deviate from traditional approaches, enabled by latest technologies. This transformation is driven by digitalization, a process essential to creating hyper-connected factories that utilize valuable data.

With Industry 4.0 encompassing the digital transformation of various industries, Print 4.0 represents the parallel concept specifically applied to the printing industry. Over the years, the printing sector has undergone a significant shift towards digitalization. As technology continues to advance, traditional printing methods are giving way to digital processes that offer numerous advantages. This transformation is driven by the need for increased efficiency, reduced costs, faster turnaround times, and the ability to meet the demands of a rapidly evolving market.

Print 4.0 enables printing companies to meet the new challenges of today's dynamic market through:

-

Automation

Embracing Print 4.0, printing companies are integrating automation into their workflows.

-

Integration

It refers to connecting different software, hardware, and systems to create a unified and efficient production environment.

-

Process optimization

Within Print 4.0, this concept allows the optimization of printing workflows for maximum efficiency. Through data-driven analysis and automation, bottlenecks are identified and eliminated, enhancing productivity and reducing errors.

-

Equipment efficiency

By utilizing real-time data and predictive analytics, printing machines' health is monitored continuously. This proactive approach identifies potential issues before they lead to downtime, reducing operational disruptions, minimizing maintenance costs and leading to increased productivity.

-

Data-Driven Insights

Print 4.0 collects vast amounts of data from various stages of the printing process. By leveraging big data analytics, companies gain valuable insights into customer preferences, production trends, and operational efficiencies.

-

Personalization

Personalization has become a key aspect of marketing and communication strategies. Digital printing has moreover revolutionized the print-on-demand model, especially in the label and packaging segments. Instead of producing large print runs, companies can now print smaller quantities based on actual demand.

-

Sustainable Printing

Digitalization and Print 4.0 contribute to a more sustainable printing industry by optimizing print processes, reducing waste, and embracing eco-friendly materials.

-

Connectivity

The advancement of digitization has underscored the importance of connectivity, allowing for more flexible work arrangements and improved accessibility to business information systems.

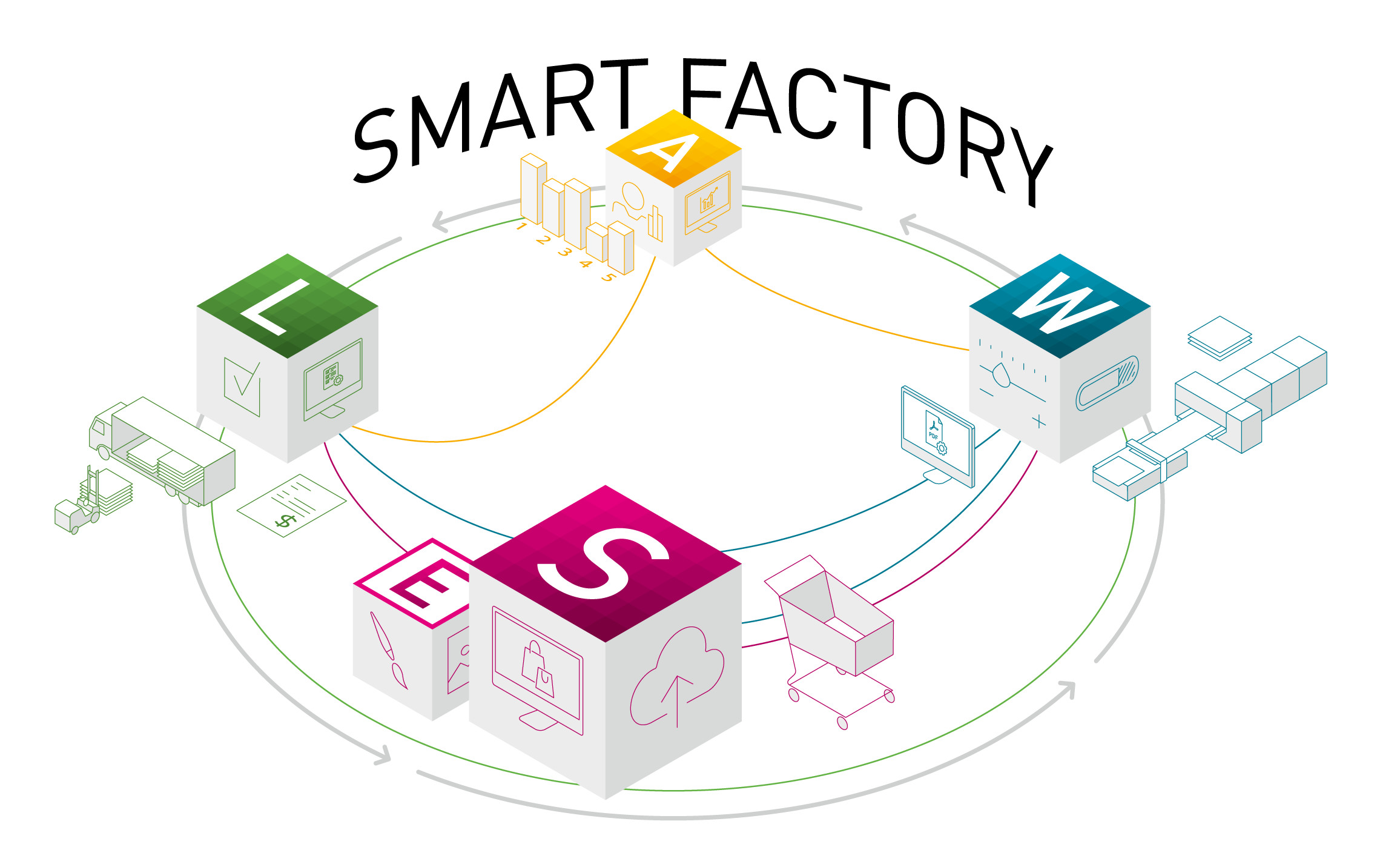

By embracing digital transformation and capitalizing on the benefits of Industry 4.0, printing companies can thrive in the digital era and maintain competitiveness in today's fast-paced and dynamic market. Durst addresses these topics with its Smart Factory approach, to make the advantages of Print 4.0 easily accessible.

Durst Smart Factory approach

In today's printing landscape, digitalization has become essential for companies.

Outdated and unproductive processes, such as using paper tickets and job bags, prove costly, time-consuming, error-prone, and difficult to circulate. Manual data entry further adds to the complexity, hindering operators from working efficiently. Therefore, streamlining and optimizing processes through digitalization becomes a crucial priority. By doing so, printing companies can focus on their core competencies and business, allowing them to be more effective and responsive to market needs. Additionally, in competitive markets, profitability and differentiation are challenging due to the persistence of unproductive processes, making it difficult to grow and find new customers quickly.

As a leading manufacturer in digital inkjet, Durst is consistently striving to develop solutions that help its customers achieve peak performance. Peak performance should be understood as the highest level of productivity in terms of flexibility in handling, stability of the system, reliability and streamlined processes. This allows for the best and most effective printing outcomes through simplified processes.

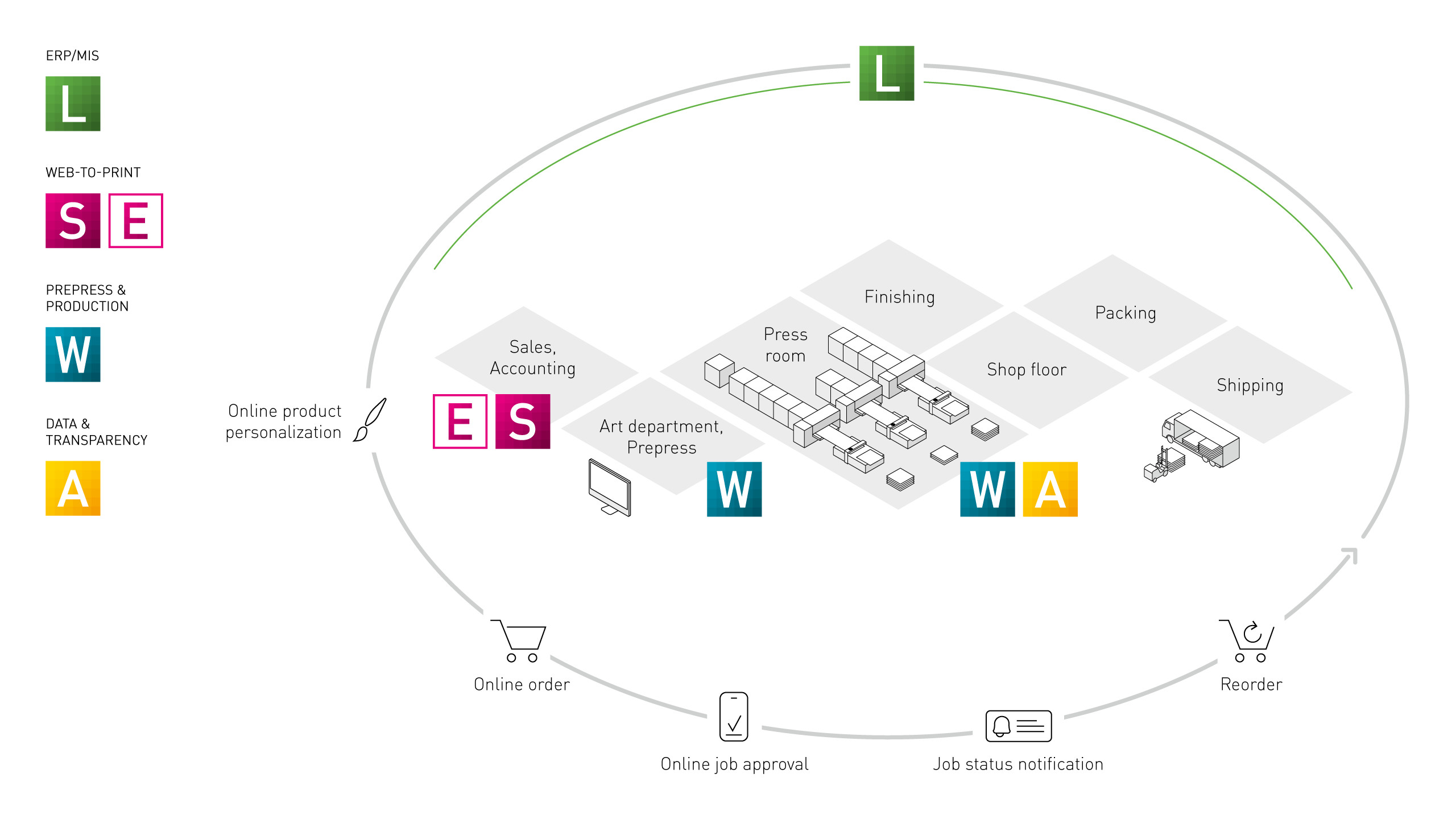

Durst's Smart Factory approach embodies the principles of Print 4.0, seamlessly integrating advanced technologies to optimize printing processes, enhance data-driven insights, and foster efficiency across the entire production lifecycle.

We offer a holistic product portfolio accompanied by a range of services, providing complete 360° business solutions. This comprehensive package includes not only printing systems but also web-to-print solutions, prepress and production software, ERP, analytics system, consulting and integration services.

Our approach offers scalable solutions, catering to businesses at different stages of growth, from start-ups to large enterprises.

-

Automate your production line

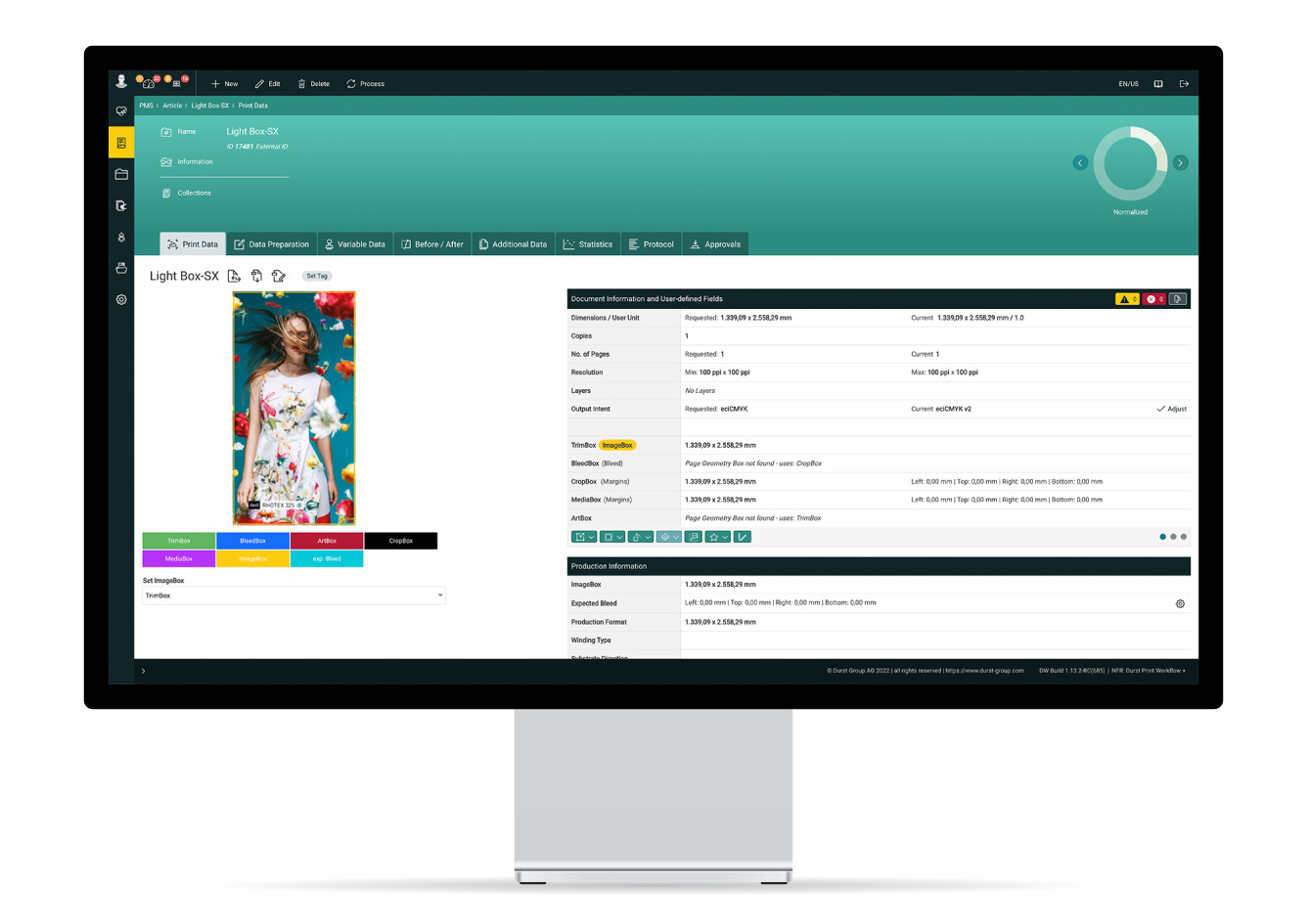

Enhance productivity, reduce error rates and any necessary reprints through defined file preparation and balanced color calibration between all printers. Streamline the printing process by reducing the need for manual intervention, minimizing errors, and cutting down on waste and material costs.

-

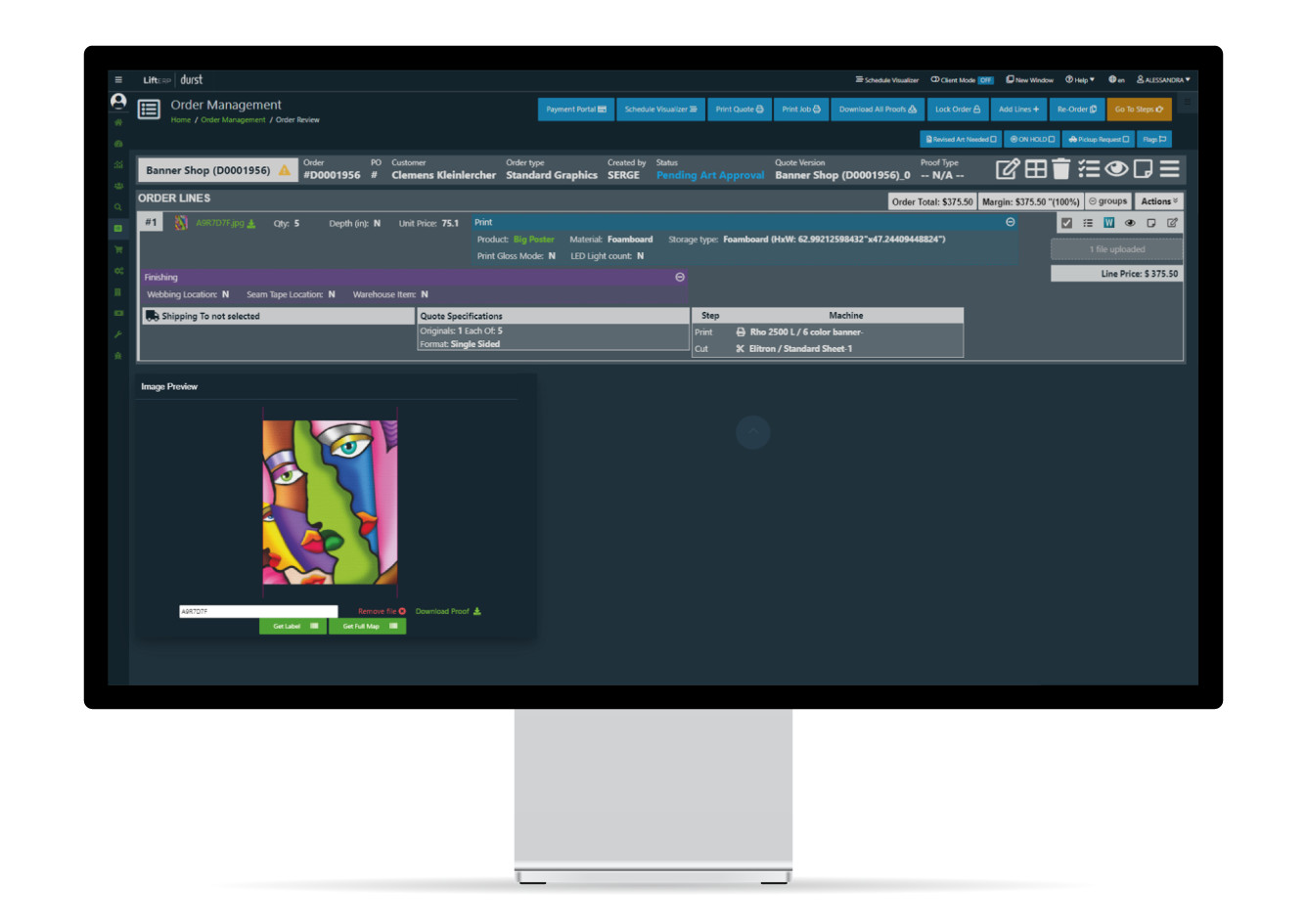

Digitize and automate end-to-end processes

Complete automation of repetitive tasks frees up time for creative work. Paperless production and embedded quality assurance increase internal efficiency, while faster turnaround times and transparent order status information keep customers informed.

-

Integrate your systems

Optimize efficiency and enhance your overall productivity: seamless coordination between different stages of the printing process reduces manual interventions and improves productivity.

-

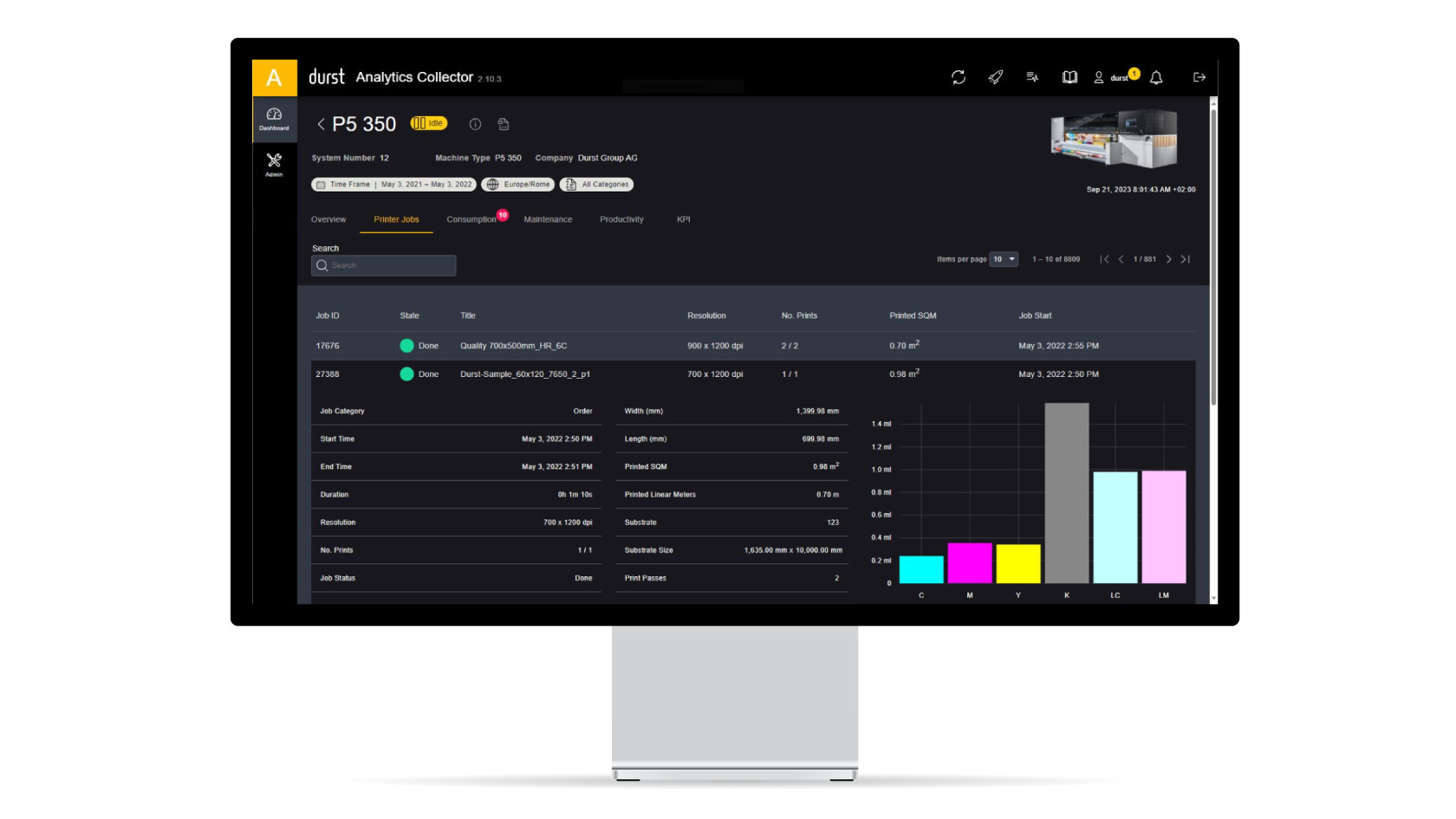

Build a data-driven strategy

Maximize business growth with a data-driven strategy. Gain control through transparency based on relevant data, enabling better decision-making and strategic planning. You can moreover monitor print production in real-time, identify bottlenecks, and make data-driven decisions to improve efficiency and quality. Our printing devices can also monitor the health of printing equipment, enabling predictive maintenance, reducing downtime, and lowering maintenance costs.

-

Embrace print personalization

Digital printing enables Variable Data Printing, allowing each printed piece to be automatically customized with unique text, images, or other elements. Web-to-print platforms further enable customers to design and customize their print materials online, improving customer engagement and response rates.

-

Enhance customer engagement

Deliver superior experience with digital touchpoints throughout the sales and fulfilment process. Implement online shops, dedicated customer portals, order tracking, mobile notifications, and automated approval processes to foster customer loyalty and involvement.

-

Embrace digital connectivity

Unlock the power of digitization and connectivity, ensure you and your team are always in the information loop, regardless of their location. Our software allows for real-time collaboration, streamlined communication, and access to essential data and resources.

Towards the Future: Trends in the Evolution from Print 4.0 to Print 5.0

As the printing industry embraces the digital revolution, Print 4.0 stands as a testament to its ongoing evolution. This paradigm shift towards digitalization has revolutionized traditional printing methods, ushering in an era of increased efficiency, reduced costs, and enhanced productivity. With a focus on automation, integration, process optimization, and data-driven insights, Print 4.0 enables printing companies to meet the challenges of a dynamic market head-on. As we look ahead, we will soon witness the dawn of Print 5.0. There will be an even greater focus on sustainability, but human-centricity will also play a major role, taking precedence and emphasizing how advanced technology like A.I. can serve people and vice versa, shifting our focus from what we can do with new technologies to what technology can do for us. In addition, supply chain resiliency will become paramount, leading us to adopt more local and regional sourcing practices to increase the resiliency of our businesses. Print 5.0 will be a significant milestone in the industry's journey to a more innovative and adaptable future, and we look forward to being part of the change.

Our Software Portfolio